In the era of rapid development for Industry 4.0 and smart manufacturing, industrial touchscreens have become the core hub for factory digital transformation. According to the latest report from MarketsandMarkets, the global industrial touchscreen market is projected to reach $8.7 billion by 2025, with a compound annual growth rate of 8.3%. Faced with such a fast-growing market, how do you choose the most suitable touchscreen for your factory? This guide will take you through an in-depth analysis of industrial touchscreen technology trends in 2025 and provide professional selection recommendations for eight key industries, including manufacturing, food and beverage, and healthcare.

The fundamental difference between industrial touchscreens and consumer-grade products lies in their design for harsh industrial environments:

Operating temperature range: -30°C to 70°C

Protection rating: Generally IP65 or higher

Mean Time Between Failures (MTBF): Over 50,000 hours

Supports 24/7 continuous operation

Multimodal Interaction Integration: Combined touch, voice, and gesture controls

AI Edge Computing Integration: Enhanced local AI processing for faster response

Modular and Expandable Design: Supports plug-and-play functionality

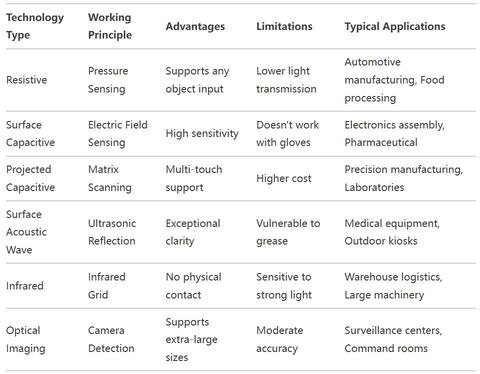

Chapter 2: In-Depth Analysis of Six Mainstream Industrial Touchscreen

Technologies

Key Requirements: Oil-resistant, anti-vibration, glove-compatible

Recommended Solution:

10-15" industrial resistive touchscreen

IP67 protection rating

Reinforced aluminum frame

Success Case: A new energy vehicle plant reduced equipment failure rates by 42% after adopting oil-resistant touchscreens

3.2 Food and Beverage Industry

Key Requirements: Waterproof, corrosion-resistant, easy to clean, HACCP-compliant

Recommended Solution:

Stainless steel capacitive touchscreen

Flush, bezel-free design

IP69K protection rating

Industry Data: Touchscreen procurement in the food sector grew 28% year-on-year in 2024.

Key Requirements: High precision, antimicrobial coating, visibility in bright light

Recommended Solution:

Medical-grade surface acoustic wave touchscreen

Anti-glare treatment

Supports repeated alcohol wiping

Breakthrough: Next-gen antimicrobial touchscreens inhibit 99% of common pathogens.

Temperature range: Standard -20-60°C -30-70°C

Protection rating: IP54 IP65 IP67 IP69K

Vibration resistance: Standard Enhanced Military-grade

Technical Parameter Checklist

Touch points: Single 5-point 10-point 20+ points

Response time: <8ms <5ms <3ms

Transmittance: 85% 90% 95%+

Industry Certification Requirements

CE/FCC/UL

Medical: FDA/CE-IVD

Food: HACCP/NSF

Self-healing Materials: Scratch-repair technology will become widespread.

Holographic Touch Interaction: Mid-air touch technology enters industrial applications.

Energy Autonomy: Solar-powered touchscreens reduce wiring needs.

AI Predictive Maintenance: Built-in sensors forecast potential failures.

Conducting comprehensive needs analysis

Considering 3-5 years of technological scalability

Prioritizing modular designs

Emphasizing after-sales service responsiveness

With the systematic analysis provided in this guide, you are now equipped with the key insights for selecting industrial touchscreens in 2025. Take action now to equip your smart factory with the most suitable interactive terminals!

Name: lily

Mobile:8613684959210

Tel:0755-27325331

Whatsapp:8618573329919

Email:sales12@huayuan-lcd.com

Add:Factory No.9, Zhongnan High-tech Intelligent Manufacturing Industrial Park, Tianyuan District, Zhuzhou,Hunan, China, 412000